Shanghai Color Digital Supplier Co., Ltd.

Professional Digital Textile Printing Equipment & Relevant Materials General Supplier

| Place of Origin: | Shanghai of China(Mainland) |

| Brand Name: | SAER |

| Certification: | CE certification |

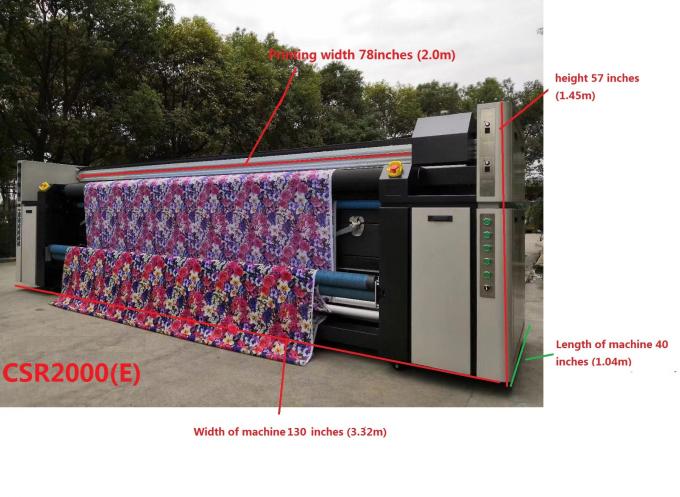

| Model Number: | CSR 2000 (E) |

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | None fumigation wooden package(Package size: 4550*1070*1550mm) |

| Delivery Time: | 10 working days after get your payment |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100 Sets Per Month |

| Product Name: | Direct Roll To Roll Textile Printer | Max Print Width: | 2000mm |

|---|---|---|---|

| Resolution: | 360-1800dpi | Working Type: | Roll To Roll |

| Print Head Amount: | Epson 4720 *3 Pieces | Color Mode: | Dual CMYK |

| Ink Supply Model: | Continuous Ink Supply | Rip Software: | Maintop 5.3 Rip Software Or Onyx Optinoal |

| Ink: | Dye Sublimation Ink / Pigment Ink | Material: | Polyester,Cotton,Wool And Silk Textile Material |

| Automatic Grade: | Automatic | ||

| Highlight: | mimaki digital printing machine,digital fabric printer,continuous inkjet printer |

||

Digital Printing Machine for table cloth with three Epson 4720 heads

Specifications:

|

Model |

CSR 2000 (E) |

| Brand | SAER |

|

Print head |

Piezo technology, 3 Epson 4720 print head |

|

Ink |

Dye sublimation ink / Pigment ink |

|

Color model |

Double 4 Color(CMYK) |

|

Print Head |

(180 nozzles x 8 lines ) x3 pieces of head |

|

Printer head higher |

1.5mm / 6mm ( Adjustable ) |

|

Ink supply model |

Continuous ink supply |

|

Max materials width |

3320mm |

|

Max printing width |

2000mm |

|

Maximum weight for roll material |

100kg |

|

Interface |

USB 2.0 |

|

RAM |

128M |

|

Printer power |

AC220-240V./AC220-240Adaptive 50/60Hz |

|

Sublimation machine |

AC220-240V. 16A. 50/60Hz |

|

Power consumption |

Direct dye sublimation heater 3500W |

|

Printer 5500w |

|

|

Temperature |

20-32°C |

|

Humidity |

40-60% Non-condensing |

|

Weight |

Net Weight :800kg Gross Weight : 965kg |

Product Features:

1· Electro thermal Heating

2· Intelligent PID Temperature Control

3· Digital Tension Control

4· Feeding and Taking up Are synchronous

5· Vacuum Fan Delivery Is Controllable

6· Quick Tail Gas Treatment

7· Convenient to Maintain

7· Easy to Set up and Operate

9. Easy to load the media in and out oven during your machine working

10. Easy to open the caver to clean inside of oven

11. Special clutch to control the feeding up system working or stop , it’s easy for you loading the roll materials.

12. Easy to change the active carbon from the filter

13. Adopting the most advanced thermal energy technology low power consumption, saves electricity and conserve energy costs.

Application :

Advantages :

Excellent After-sale Services:

1.Customized Service:

We Can Provide Customized Production and Packing for You!

2.Training Service:

We Provide FREE Training for Our Clients! Even can Send Engineer to Oversea Local Customer!

3.Guarantee Service:

We Provide one year Warranty for All Industry Machine Models!

4.Solution Service:

The Most Important We Have Digital Printing Solution Ability!

We Have Provided Many Digital Inkjet Printing Solutions for Over 30 Clients Per Year! Some of Them are Very Famous Printing Company!